SENSYN ROBOTICS Inc. and Chubu Electric Power Grid Co., Inc. have been jointly developing an AI to automatically detect abnormalities in power transmission facilities.We are pleased to announce that we have newly developed an AI to detect tower bolt dropout and rust, as well as to expand the scope of real-time abnormality detection, and that we have decided today to introduce this AI for the inspection of transmission facilities owned by Chubu Electric Power Grid.

SENSYN ROBOTICS and Chubu Electric Power Grid have jointly developed automatic inspection technology for power transmission facilities using drones, implemented this technology in “POWER GRID Check”, a business application specialized for maintenance work on overhead power transmission facilities, and started on-site operation in 2021. This technology enables automatic and high-quality inspection and imaging of facilities without the need for advanced piloting skills. On the other hand, the acquired images were checked visually by workers, which required a great deal of labor and left the judgment of abnormal locations to the experience of individual workers.Therefore, by developing an AI that detects abnormalities through image analysis and implementing it in “POWER GRID Check,” it has become possible to automatically perform everything from image acquisition by the drone to the determination of abnormalities.

Technology Establishment Results

◾️Real-time Anomaly Detection AI

From the viewpoint of ensuring public security, it is necessary to promptly detect abnormalities that may cause disasters to third parties. We have developed an AI that detects abnormalities such as broken or melted wires and damaged or chipped insulators in real time based on real-time images (live stream images) from drones transmitted to mobile devices, and have already started on-site operation in FY2023. In addition, we have developed a new AI that detects in real time the loss of a dead weight of a “damper “*1 or the detachment of a gripping part of a “spacer “*2, which are accessories of electric wires.

*1 A device to suppress vibration and snow growth on electric wires.*2 A device to keep electric wires at a specified distance from each other.

“Real-Time Abnormality Detectionfor Insulators”“Display of Results After Real-Time Abnormality Detection for Power Lines”

“Detection of ‘Dampers’ and ‘Spacers’ Using a Mobile Application”*The screen is from a development stage.

◾️AI for steel tower bolt dropout and rust detection

Regarding abnormalities related to steel towers, we have newly developed an AI that detects “bolt” dropout and steel tower rust. The AI learns and evaluates by tower type (angle steel tower and pipe steel tower) and by tower paint color (unpainted, rust-proof paint (gray), aviation sign paint (red and white), and environmental paint (brown)), so it can detect various types of steel tower anomalies.For “steel tower rust” detection, it is also possible to classify the ranks according to the degree of rust.

“Normal Image”“Image after rust detection”

“Rust Abnormality Detection Interface”

Future Outlook

The newly developed AI for detecting abnormalities related to “dampers,” “spacers,” “bolts,” and “tower rust” will be implemented into ‘POWER GRID Check’ during the 2024 fiscal year, with field operations set to begin. The results of abnormality detection will be highlighted and viewable within ‘POWER GRID Check.’ Since the developed AI models require continuous learning to improve accuracy, we will build a scheme to enhance AI performance through re-learning and algorithm selection based on user feedback.

Additionally, we are conducting joint research and development with the goal of applying this technology to substation equipment. The AI technology for detecting instrument indications, which has been established for substation operations, is also planned to be implemented into ‘POWER GRID Check’ from the next fiscal year onwards. We will continue to develop the application to handle not only transmission equipment maintenance but also substation maintenance and operations, with the aim of applying it across the entire general power transmission and distribution business.

What is ‘POWER GRID Check‘?

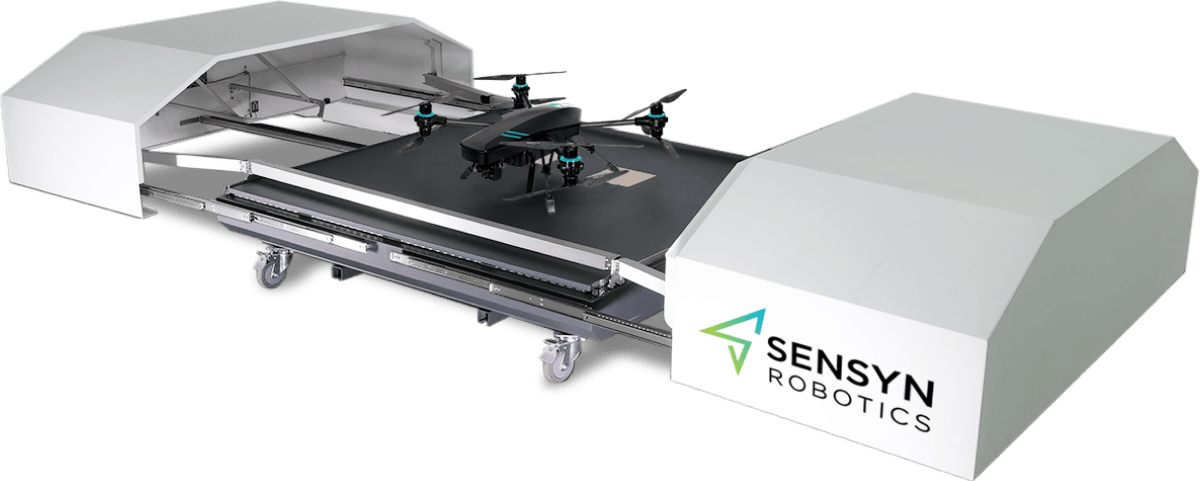

‘POWER GRID Check’ is a transmission equipment inspection application that utilizes drones, based on technology jointly developed by Sensyn Robotics and Chubu Electric Power Grid. It is characterized by its ability to automatically inspect transmission towers (supports and insulators) and transmission lines (ground wires and power lines) in one go. The application ensures a safe distance between the drone and the equipment while performing automated flights to collect consistent data, allowing workers without specialized knowledge of drones to easily conduct transmission line inspections.

About SENSYN ROBOTICS

SENSYN ROBOTICS is a leading company in the field of social infrastructure DX with the mission of “evolving the ‘natural’ in society. SENSYN ROBOTICS is a leading social infrastructure DX company that uses the power of AI and data to solve the problems faced by society and businesses.We solve issues such as labor shortages, safety risks, and rising costs that exist in the social and industrial infrastructure that supports Japan and the world with software solutions for data utilization that anyone can handle, making full use of the latest technologies, including AI.Utilizing the know-how gained from a wealth of projects and our proprietary software development platform “SENSYN CORE,” we provide comprehensive support from consulting to scenario formulation, business feasibility evaluation, technology and system development, and implementation in actual operations. We will help realize a sustainable future by solving social issues such as inspections of aging infrastructures, a declining workforce due to the falling birthrate and aging population, and increasingly severe disasters.

Head Office:4F Sumitomo Fudosan Oimachiekimae Building 1-28-1 Oi, Shinagawa-City, Tokyo JapanEstablished:October, 2015CEO:Takuya Kitamurahttps://www.sensyn-robotics.com/en

Discover more from sUAS News

Subscribe to get the latest posts sent to your email.